Get Ready for Labelling

Retailers need to prepare and Get Ready as the requirements for prepacked for direct sale (PPDS) food labelling will change in Scotland, England, Wales and Northern Ireland from 1st October 2021.

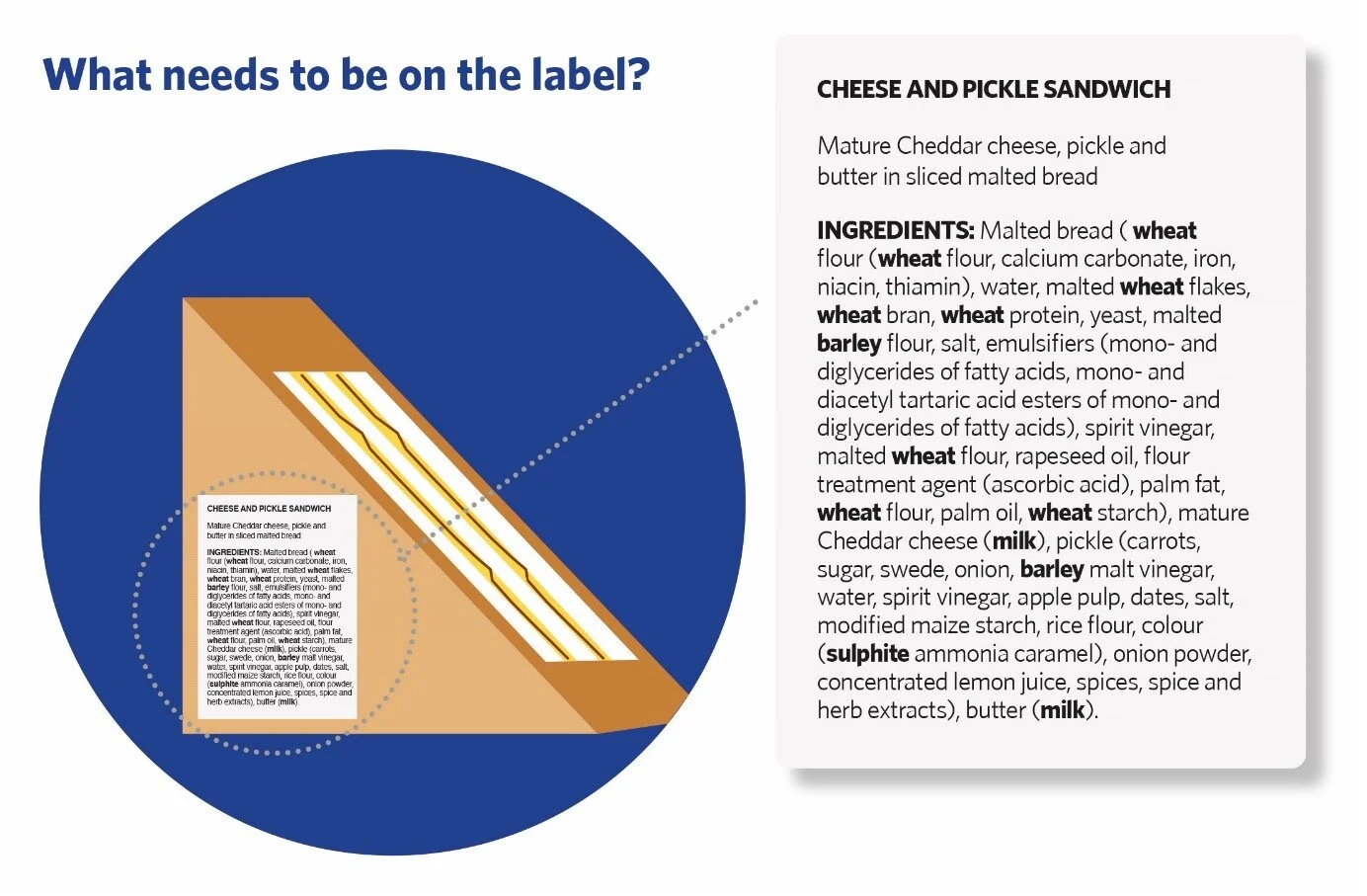

This means that any business that produces PPDS food will be required to label it with the name of the food and a full ingredients list, with allergenic ingredients emphasised within the list.

What is and what is not PPDS food is explained in Parts 1 and 2 respectively of this retailer guide.

Where do I start, what should I do to Get Ready?

A good place for retailers to begin is to consider what processes and procedures are going to have to put in place and how this will be managed.

Below are some of the questions which retailers may wish to take into consideration and reflect upon to enable them to begin their preparations for PPDS food labelling.

Questions

Have you done any food labelling previously?

How much time do, or did you need to spend getting ready to set up a labelling system?

Products

What type of products do you intend to label?

Do you use standard recipes?

How do you record this information?

Could you adapt your existing approach for tracking allergen information to include ingredients and their quantities?

How long did it take to work out the ingredients for each product line? Are some more complicated than others?

What quantities of each product would you expect to label each day or when you make a particular product?

How do you handle last minute ingredient substitutions and how is this recorded?

This is not an exhaustive list of questions and other matters will need to be thought about by retailers such as for example, sourcing a suitable labelling system, and the time and operational costs associated with setting it up and maintaining it.

Advice from the Food Service Sector

Awareness & Preparation

A sound understanding of the requirements of the Legislation and preparation in advance to ensure the information is in hand and ready to use. A risk assessment is essential to ensure you have considered all the risks associated with food preparation on your premises

Identify hazard control points

Cross contamination is vital

Use dedicated storage for allergenic material

Use dedicated preparation areas and equipment for allergen free food where possible

Follow cleaning best practice and good hygiene

Only use ‘may contain’ when there is a genuine risk and not as a substitute for good hygiene and food safety practices

Identifying Allergens

Assess what allergens are being handled within your business

Always audit deliveries to ensure the products and label declarations comply to your usual supply

Look out for hidden allergens (eg Vinegar – is it spirit or barley (barley being an allergen)

Always check for ‘May contain’ statements on ingredient lists

Training of staff

It is essential that all staff involved in the preparation of the products and the Food Business Owners are fully trained to recognise any of the 14 Major Serious Allergens:

Celery, Cereals containing gluten (wheat, oats, barley, rye, spelt, corn), Crustaceans (crabs, lobster, prawns)

Eggs, Fish, Milk, Lupin, Molluscs (oysters and mussels), Mustard, Sesame, Peanuts, Soybeans, Sulphur dioxide and sulphites (for concentrations above ten parts per million – not easy to determine and always best to declare), Tree nuts (almonds, walnuts, brazil nuts, hazelnuts, pecans, cashews, macadamias, and pistachios)

Training of the staff should include the following:

Ensure ALL employees are trained

Instruct staff to ask every customer about their allergen concerns

Regularly review and record staff training

Cross contamination:

Although a product packed for the consumer may not contain all the allergens used on the premises it is advisable to ensure the consumer is aware that their product ‘MAY CONTAIN’ other allergens. It is entirely feasible that even in the most organised preparation areas that there will be a risk of products containing different allergens coming into contact with each other but not intended for the same finished product.

You will identify any cross contamination risks during the risk assessment process (detailed above). Clear and accurate information to the customer can be achieved by a printed notice that states all the allergens used on the premises. The consumer is then fully aware of the possibility of cross contamination and can make a considered judgement.

Where do you find the allergen information on the products you buy

All products supplied by Food Service operators should be fully labelled and already comply with the ‘Food Information to Consumers Act 2014’ whereby all manufactured and packaged goods must be labelled with full ingredient declarations and allergens clearly detailed and highlighted on the label.

Reference to the label is the fastest way to get the information you need when preparing products.

Product specifications are maintained on file your Food Service supplier and are available on request.

Important

For additional information you can also use the interactive questionnaire to help you determine if you are selling prepacked for direct sale food.

Retailer journey

For many retailers, particularly those who may own only one small store, the transition to a mandatory food labelling system for prepacked for direct sale food may seem a daunting prospect.

In recognition of this and to help explain what is involved we have the experiences of two convenience store retailers who have already made the transition to a food labelling system for PPDS food. They share their own journey of how the transition has worked for them.

Abdul’s story

“We made the transition to PPDS food labelling before the legal requirement to do so. We felt it was important that our customers were aware and informed of the allergen and food ingredients information in the food products that they purchased and for the labelling to act as a guide for them.

Once we adapted to listing allergens, the key thing thereafter was to also to be aware of all the ingredients. It is key that retailers providing PPDS food understand the flow of ingredients in their food whether they be provided in-house or from the wholesalers. We initially found it a time-consuming process to understand the flow of ingredients for products. It is now a lot easier given that more companies can give you all the ingredients information that you need.

The downside is the huge difference in costs associated with food labelling when compared to previously. Now it can cost as much as 6p or 7p per label. In our view however it is worth it to give the consumer all the information at the time of purchase, everything they need to know is now labelled on the products. From that point of view, it is worth it for us.

Our food labelling gives customers confidence when they are making their purchase as they can see all the allergen and ingredients information that they need to know about. Confidence is provided for customers prior to purchase and in our view, it is worth that extra effort.

We would advise retailers that they should not wait to start food labelling and that they start right away. As a business it makes sense to give customers the information they need at the time of purchase. There are now more labelling solutions and food labelling companies available for retailers to choose from. Food labelling keeps you legal and customers are confident.

Do food labelling as it is the right thing to do - the health of the customer is paramount - not because you are forced to.”

Dan’s story

“Using food labelling has simplified everything and I have used it for several years. If you are doing a volume of PPDS food products, the use of a food labelling system simplifies things for the retailer.

Labelling software lets you keep a database of ingredients for recipes without worrying about mistakes being made. It also saves retailers time and from any complication and is much better than using handwritten labels and having to keep associated records.

There is a time commitment to initially setting up a food labelling system and it is important that it is done so properly. If you cut corners setting up the database things can become complicated. If you set up correctly however, making changes to allergen and ingredient information are easy to do with a food labelling system in place. There is also a time commitment involved for the initial training that is required to become familiar with how the labelling software works. This time needs to be managed and merged into your usual routines. It is important that you update the food labelling database as soon as product ingredients are changed. Food labelling would be ten times harder without the software.

It has simplified things for us and there is no handwriting or manual work. The software also lets you go through the database and to print off labels. These labels look professional. The detailed information on the label provides the customer with information they need and so minimises the risk to them. You will face more difficulties if you do not do labelling. Food labelling software and labelling companies will keep you legal.

Food labelling gives customers a more professional perception of the products you are selling. It can provide them with nutritional, allergenic and food ingredients information that they require. They want to see this information. A lack of such information was previously stopping customers from making a purchase however with the changeover to labelling you can then gain more customers.

Labelling also makes customers more confident in your food hygiene and presenting your products in a clean, professional way, gives the perception that you prepare your food that way.

I would strongly advise retailers to do food labelling. If you are making any products yourself, you can save yourself time and risk. Take time to act now as the transition does not happen overnight and you also need to input ingredient information etc on the labelling database. Act as quickly and diligently as possible and then amend and change the ingredients thereafter as you need to. Also identify what food labelling system and software you need as well as getting a printer as demand for these services will only increase as we near the 1st October deadline, so best to take action now.

Your new labelling system does not have to be anything complicated, explore the different options and maybe start with a basic solution at first. You can then build it up from there to the point where for example you can have labels designed for you.”

These case studies are intended to act as a guide only as every retailer will have their own specific set of circumstances to deal with, however, they are intended to provide learnings and experience of some retailers who have already made the change to PPDS food labelling.